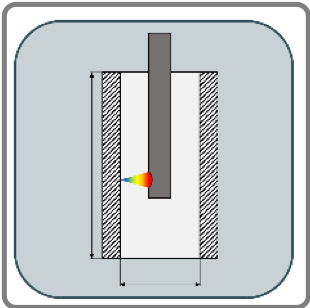

9 SIT: Inspection tool for measuring geometrical features of bores

Accurate dimensional measurements are of key importance in high-precision mechanical components.

This quality control system exploits confocal chromatic technology to measure geometrical features of turned parts (diameters, length, holes/grooves extensions/relative locations). By exploiting this non-contact technology, the system can measure on parts of different size and material without the need to change the testing probe, as it happens for standard contact measuring device.

Being temperature-compensate, the system can be installed and used in-line. This, as well as the probe-to-target auto-centering strategies, makes it possible to achieve a measurement accuracy less than 0.01 mm.

Information

- Paper: P. Chiariotti, M. Fitti, P. Castellini, S. Zitti, M. Zannini, N. Paone, Smart Quality Control Station for Non-Contact Measurement of Cylindrical Parts Based on a Confocal Chromatic Sensor, accepted for publication in IEEE Instrumentation & Measurement Magazine (proof just sent)

- Paper: P. Chiariotti, M. Fitti, P. Castellini, S. Zitti, M. Zannini, N. Paone, High-accuracy dimensional measurement of cylindrical components by an automated test station based on confocal sensor, Conference proceedings of IEEE International Workshop on Metrology for Industry 4.0 and IoT 2018, Brescia (Italy), April 16-18, 2018. (Access)

- Paper: Chiariotti P., Fitti M, Castellini P., Paone N., Minnetti E., Cristalli C., Angione G., Lo Duca G., Concettoni E. (2018), “Smart measurement systems for Zero-Defect Manufacturing”, Proceedings of 16th IEEE International Conference on Industrial Informatics (INDIN 2018). (Access)

- See this Tool in Action!

- GO0D MAN Webinar on Smart Inspection Tools

- GO0D MAN Deliverable D3.1 - Quality Inspection Systems

- GO0D MAN Deliverable D3.2 - Self-Adaptive Quality Inspection Systems